In today’s industrial landscape, plastic molding stands as one of the most crucial manufacturing techniques. Whether it’s in automotive, medical, electronics, or consumer goods, molded plastic has become a backbone of modern production. The flexibility, cost-efficiency, and scalability of this process make it indispensable for businesses around the world. As industries continue to evolve, the importance of a reliable plastic molded parts manufacturer or a trusted plastic parts company cannot be overstated.

Understanding Plastic Molding in Modern Manufacturing

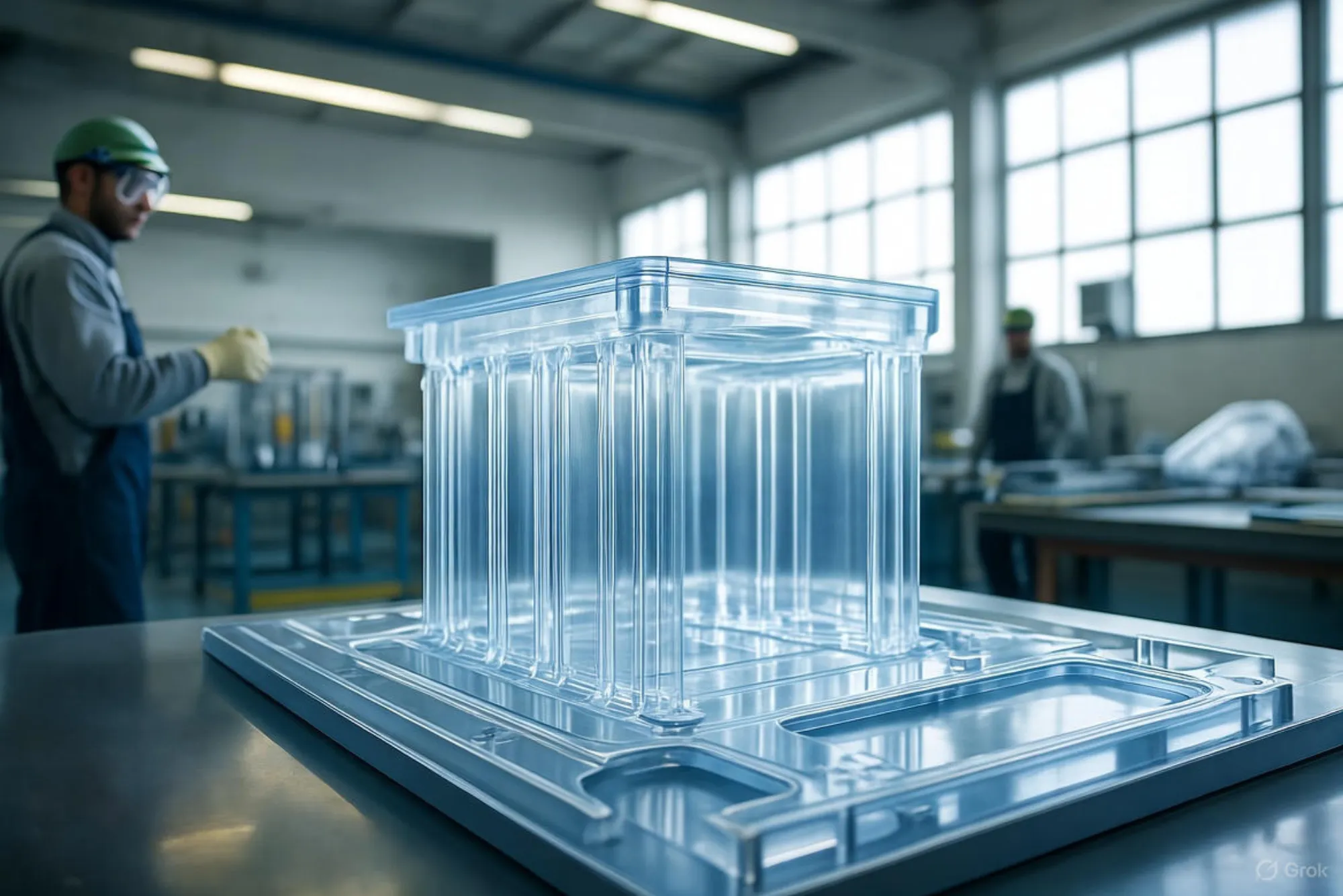

Plastic molding is the process of shaping plastic material into desired forms using molds and specialized machinery. There are various methods such as injection molding, blow molding, and compression molding, each tailored to different types of products and materials. What makes plastic molding essential is its ability to produce high-precision components at a large scale, with consistency and reduced costs compared to alternative manufacturing techniques like metal machining.

Consider the smartphone in your pocket. Almost every visible component—from the sleek casing to the internal clips holding the circuit board—is molded plastic. Without plastic molding, mass production of such consumer technology would either be too expensive or simply impossible at the current speed.

Cost-Effectiveness and Scalability

One of the primary reasons plastic molding dominates modern production is its cost efficiency. Once a mold is designed and built, it can be used repeatedly to produce thousands or even millions of identical parts with remarkable precision. This reduces both material waste and labor costs.

A plastic molded parts manufacturer is especially valuable to companies looking to scale production without drastically increasing overhead expenses. Instead of investing in multiple types of equipment for different components, businesses can rely on a single mold setup to create parts in bulk. This efficiency is a critical factor in keeping consumer prices affordable while allowing manufacturers to remain profitable.

Versatility Across Industries

Plastic molding is not confined to one sector—it spans industries that touch every part of our daily lives. In healthcare, molded plastics are used for syringes, IV connectors, and even components in life-saving medical devices. In automotive, molded parts include dashboards, bumpers, and intricate clips that hold a vehicle together. In consumer goods, everything from toys to kitchen appliances relies on plastic molding for durability and affordability.

Working with a specialized plastic parts company ensures that businesses can access the right type of molding process for their specific industry needs. For example, an electronics brand may require high-precision injection-molded casings resistant to heat, while a medical supplier might need sterile, single-use molded parts produced under strict quality controls.

Innovation and Customization

Another advantage of plastic molding lies in its capacity for innovation and customization. Modern molding techniques allow manufacturers to experiment with various plastics, composites, and additives, enabling products that are stronger, lighter, or more heat-resistant.

For businesses seeking competitive differentiation, partnering with a forward-thinking plastic molded parts manufacturer can open doors to new design possibilities. Custom colors, textures, and structural reinforcements can be built into the production process without significantly increasing costs. This adaptability ensures that molded plastic parts meet both aesthetic and functional requirements.

Quality and Consistency

Quality control is vital in modern production, and plastic molding excels in this area. With advanced injection molding machines, the margin of error is minimal. Parts are produced with uniform thickness, strength, and appearance, ensuring consistency across thousands of units.

A professional plastic parts company often employs rigorous inspection systems, including automated sensors and human oversight, to verify that every part meets exact specifications. This reliability is especially important in industries like aerospace or healthcare, where even the slightest variation can compromise safety.

Sustainability and Environmental Considerations

Sustainability has become a pressing concern for modern production, and plastic molding is evolving to meet these expectations. While plastic as a material has long been criticized for its environmental impact, new innovations are helping to reduce its footprint. Recycled plastics, biodegradable polymers, and closed-loop manufacturing processes are increasingly being adopted by forward-thinking companies.

Partnering with a responsible plastic molded parts manufacturer can help businesses align with global sustainability goals. Many manufacturers are now investing in eco-friendly materials and efficient machinery that consume less energy, creating products that are both affordable and environmentally conscious.

Real-World Example: Automotive Industry

To see the importance of plastic molding in action, consider the automotive sector. Modern vehicles contain hundreds of molded components—from the smallest clips to large exterior panels. Without molded plastics, cars would be significantly heavier, less fuel-efficient, and far more expensive to produce.

Here, the role of a reliable plastic parts company is pivotal. Automakers depend on suppliers who can consistently deliver parts that not only meet strict quality standards but also integrate seamlessly into large-scale assembly lines. The consistency, affordability, and design flexibility of plastic molding keep the automotive industry moving forward.

The Role of Manufacturers in Driving Growth

While plastic molding itself is a remarkable process, the expertise of the companies behind it is what truly drives success. A seasoned plastic molded parts manufacturer brings engineering knowledge, material expertise, and production efficiency to the table. They act as strategic partners to brands, guiding them through design challenges, material selection, and scaling production for global markets.

Likewise, a dedicated plastic parts company can support startups as well as established enterprises, ensuring they have access to high-quality molded components regardless of production volume. This partnership is what enables businesses to bring innovative products to market faster, more affordably, and with fewer risks.

Conclusion: Why Plastic Molding Will Continue to Shape the Future

Plastic molding is not just important—it is foundational to modern production. Its ability to deliver cost-effective, high-quality, and scalable solutions makes it one of the most reliable manufacturing processes of our time. From healthcare to automotive and consumer goods to electronics, molded plastics form the invisible yet essential backbone of the products we rely on every day.

As industries demand more sustainable and innovative solutions, the role of the plastic molded parts manufacturer and the plastic parts company will become even more central. Businesses that understand and leverage this process will not only stay competitive but also contribute to shaping a future where production is efficient, sustainable, and forward-looking.